Custom Precision CNC Machined Parts with 100% Inspection and Guaranteed Quality for Brass Aluminum Steel Components

-

ハイライト

Custom Precision CNC Machined Parts

,100% Inspection CNC Turning Milling Parts

,100% Guaranteed Precision Machined Components

-

許容範囲±0.002 ~ ±0.005mm

-

表面の粗さRA 0.1〜3.2

-

材料能力アルミニウム、真鍮、青銅、銅、硬化金属、貴金属、ステンレス鋼、鋼合金

-

表面処理陽極酸化、ビーズブラスト、シルクスクリーン、PVDメッキ、亜鉛/ニッケル/クロム/チタンメッキ、ブラッシング、塗装、粉体塗装、不動態化、電気泳動、電気研磨、ローレット、レーザー/エッチング/彫刻

-

処理方法、回る、CNC切れるレーザー切れる、回る、曲がること、ワイヤー、CNC製粉する機械で造る放電(EDM)、射出成形押す

-

アルミニウムシリーズ2000シリーズ、6000シリーズ、7075、5052

-

ステンレス鋼の等級SUS303、SUS304、SS316、SS316L、17-4PH

-

鋼鉄等級1214L/1215/1045/4140/SCM440/40CrMo

-

ブラスグレード260、C360、H59、H60、H62、H63、H65、H68、H70、ブロンズ、銅

-

チタニウムの等級グレード F1 ~ F5

-

プラスチックタイプアセタール/POM/PA/ナイロン/PC/PMMA/PVC/PU/アクリル/ABS/PTFE/PEEK

-

描画形式dxf / dwg / step / igs / pdf

-

マイクロ加工はい

-

CNC加工はい

-

検査レベル重大な次元の100%の点検

-

起源の場所中国広州

-

ブランド名YWY

-

モデル番号YWY021、OEM

-

文書

-

最小注文数量1

Custom Precision CNC Machined Parts with 100% Inspection and Guaranteed Quality for Brass Aluminum Steel Components

Custom Precision 0.01mm Tolerance Brass Aluminum Steel CNC Machined Turning Parts with Plating

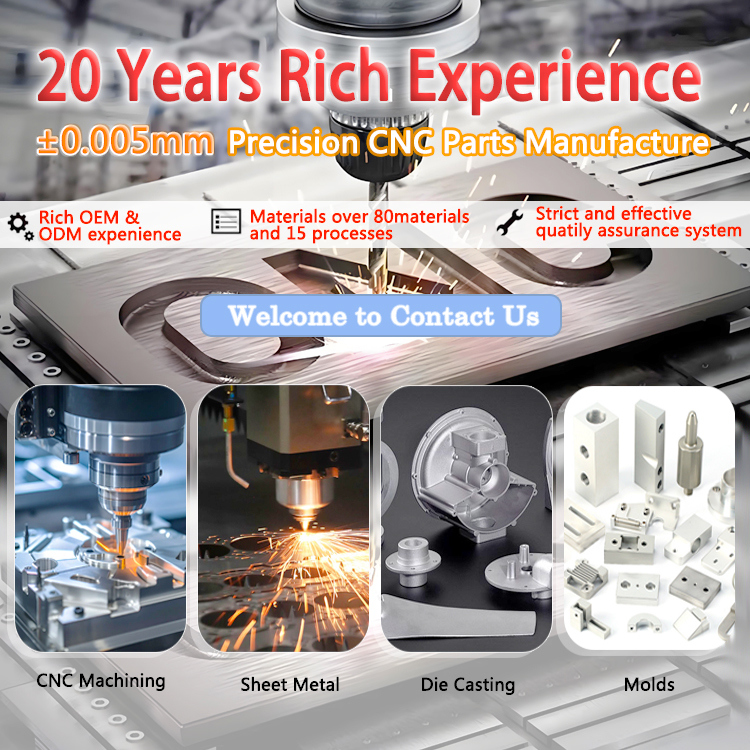

Our Manufacturing Capabilities

| Processing | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|---|---|

| Materials |

|

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Tolerance | ±0.002 ~ ±0.005mm |

| Surface Roughness | Min Ra 0.1~3.2 |

Factory Showcase

Product Gallery

Customer Projects

Frequently Asked Questions

1. Are you a manufacturer or a trading company?

We are a 1500-square-meter factory located in Huizhou, China.

2. Can I get a quote without drawings?

Yes, we can provide quotes based on your samples, pictures, or drafts with detailed dimensions.

3. Will my drawings be divulged if you benefit?

No, we strictly protect our customers' intellectual property and can sign NDAs when required.

4. Can you provide samples before mass production?

Yes, samples are available with a fee that may be refunded upon mass production order.

5. How about the lead time?

Typically 1-2 weeks for samples and 3-4 weeks for mass production.

6. How do you control the quality?

- Material inspection - Surface and dimensional checks

- Production first inspection - Critical dimension verification

- Sampling inspection - Quality control during production

- Pre-shipment inspection - 100% final inspection before delivery

7. What will you do if we receive poor quality parts?

We will immediately analyze the issue and remake the parts at no additional cost.